Here Are the 4 Types of FDA Inspections You Need to Understand

Every medical device manufacturer knows that, at some point, they should expect the FDA to arrive to conduct an inspection.

Often there may be no advance warning - you’ll walk into the office one day and find an inspector waiting to get started. For this reason, there is often a lot of angst over inspections, although there doesn’t have to be! You can breathe a little easier if you put some time into preparation, as we have looked at previously on the blog.As part of that, you really should know that the FDA may conduct any of four different types of inspection, depending on the purpose and timing. Overseas manufacturers who produce devices for the US market can also expect that the FDA to come in and conduct an inspection. Let’s take a look at the four types:

Free Checklist: A checklist for responding to FDA 483 Observations and Warning Letters.

1. Pre-approval inspections

Has your company made a submission to the FDA requesting to market a new product? If so, you can expect that a pre-approval inspection is highly likely. The purpose of these inspections is to verify the data you have included on your application and to confirm that your facility is suitable for manufacturing the device.

The FDA gives some information on this process in its documentation. You will usually have five days advance warning, unless your company has had violations in the past, in which case you may get no notice at all. Some facilities may not get a pre-approval inspection at all, but the FDA determines this with a risk-based approach, looking at product, facility and process risk.

Process risk may include an assessment on things like the seriousness of the condition the device treats or the patient population it is aimed at. Facility risk may include looking at things like the history of the facility (have there been recalls or non-compliances in the past?) and factors, such as several applications being filed at once. As for process risk, the FDA will look at factors like your development data and whether the process is significantly different to any you have done before.

If you are getting a pre-approval inspection, that at least means that your PMA submission demonstrated that you meet QMS requirements and are ready for inspection, here’s what the FDA says on it:

In making the determination of the firm's ability to design, manufacture or process the device, the Office of Compliance (OC) may issue an inspection assignment to the appropriate FDA district office. The inspection assignment will be issued when OC has determined that the manufacturer has demonstrated in the PMA submission that the design and manufacturing process meets the QS regulation requirements and the facility is ready for inspection.

The specific guidelines for pre-marketing inspections can be sourced from the FDA so it is possible to prepare ahead and know what they will be looking for. The possible outcomes of an inspection are that the inspector will either recommend for or against FDA approval.

2. Routine inspections

These are the inspections mandated by law to be expected every two years for manufacturers of Class II or Class III medical devices. Again, you may get a five-day advance notice, or you may find inspectors in your office unannounced. The ideal scenario is that, if you manufacture Class II or III devices, you conduct your operations as though that inspection might arrive on any given day, thus preparing ahead.

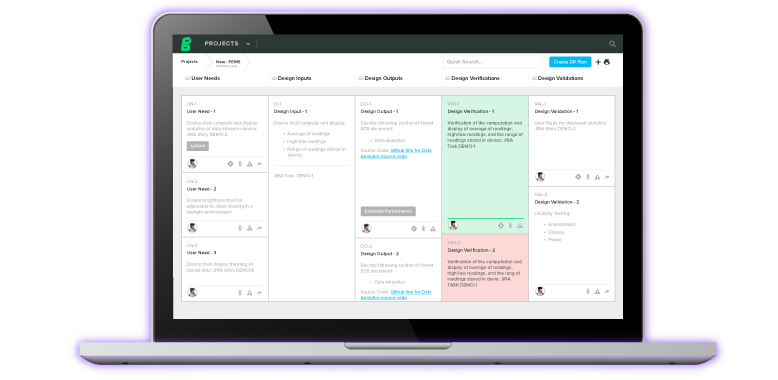

The purpose of routine inspections is to follow the Quality System Inspection Technique (QSIT), to systematically assess whether your company is following compliance requirements. This targets the four major subsystems of your quality system; corrective and preventive actions (CAPA), design controls, management controls and production and process controls.

There are two levels of QSIT inspections:

- Level 2 Baseline QSIT - This is very comprehensive and covers all four of those subsystems. You can expect this type of inspection when you have never undergone one before, then every six years thereafter.

- Level 1 Abbreviated QSIT - As the name suggests, this is a shorter inspection that is conducted after you have already had the Level 2 previously. These inspections will always include your CAPA system, plus one other of the major subsystems. They will usually choose a different subsystem for subsequent Level 1 inspections.

To sum that up, you can expect your first inspection to be a Level 2, then Level 1 inspections in the subsequent 2 year periods, up until 6 years after that first Level 1 inspection, when you can expect to have another comprehensive inspection.

Of course, frequency and type of inspections can very much depend on what the inspectors find. If they find any non-compliance issues or have to issue any 483 observations or warning letters, you can expect them to be back sooner, and possibly to be conducting follow-up or “for cause” inspections. If you’ve had significant issues, it’s possible that they’ll be back to conduct another inspection much sooner than that two year period.

3. Compliance follow-up inspections

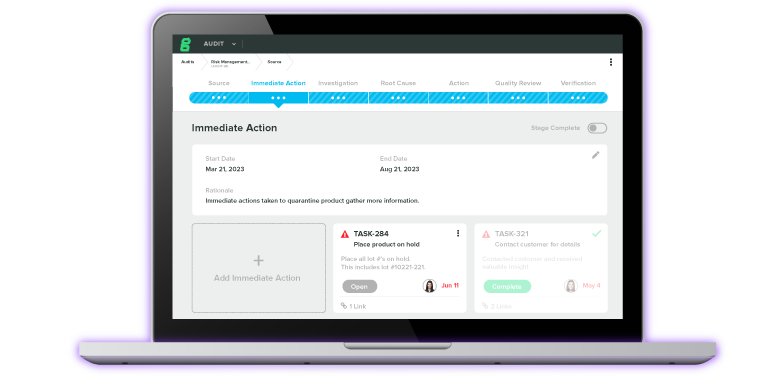

If your company was issued with significant 483 observations or any warning letter, the FDA will want to come back to inspect and verify the actions you have taken in response to those observations.

They are checking that you have responded adequately and corrected any previous violations. If not, they may document current violations and use that as evidence to support future regulatory action.

You will almost never have notice of this type of inspection, although you can be prepared nonetheless. If you had 483 observations or any warning letter, you will be aware of the exact issues that the FDA found and should take action as soon as possible to address them. When they show up for compliance follow-up, it is those issues that they identified that they’re wanting to verify have been taken care of. Our tip would be to just be prepared. Get those violations corrected and you shouldn’t have to be worried about when a follow-up might happen.

4. “For cause” inspections

This is the type of inspection that can catch manufacturers unaware, although they definitely don’t happen as often as the other three. “For cause” inspections happen where there has been an issue reported to the FDA, such as from consumers or employees. In some cases, you may have reported to the FDA yourselves, especially in the case of any significant harm or a product recall (expect a “for cause” inspection in these cases).

There are no guidelines for manufacturers for these types of inspections as they tend to be unscripted. Sometimes the inspector has a specific assignment that won’t be made publicly available.

These inspections may be very in-depth and may not follow the QSIT. Inspectors have free-reign and they might decide to branch into other areas of your firm’s operations that are outside of the specific issue that lead them there.

You will not get advance notice of this type of inspection, so the best policy tends to be prepared as you would be for a regular inspection. Have a good QMS in place and keep it up-to-date, as well as keeping up with your Management Reviews and internal inspections.

Free Checklist: A checklist for responding to FDA 483 Observations and Warning Letters.

Final thoughts

As medical device manufacturers, you can expect to be inspected. There are clear guidelines for those first three inspection types, so you can familiarize yourself with them and be prepared ahead of an inspector arriving.

While a “for cause” inspection may follow a longer, unscripted format, the FDA is still overall interested in the safety and efficacy of your device, and that those four key QMS subsystems are adhered to.

Put your company in a better position for any inspection by having an efficient, centralized QMS. Interested in trying something cloud-based for ease of management and use? Take a look at Greenlight Guru. We offer a great solution which can be implemented quickly.

Jon Speer is a medical device expert with over 20 years of industry experience. Jon knows the best medical device companies in the world use quality as an accelerator. That's why he created Greenlight Guru to help companies move beyond compliance to True Quality.

Related Posts

Top 7 QMS Tools for MedTech (Plus 4 Bonus Resources)

eIFU Requirements: Everything You Need to Know About Electronic Instructions for Use

What are the SaMD Requirements from FDA?

Get your free resource

Responding to FDA 483 Observations and Warning Letters Checklist