Best Practices for Implementing Design Controls for the Medical Device Industry

.png)

If you're like many in the medical device industry, you've probably had some questions at one time or another around the FDA's Design Control Guidance.

And if you're anything like the guests on today's podcast, you've probably gone through a lot of trial and error trying to implement them.

Wouldn't it be nice if some industry vets were willing to share with you their proven best practices and top recommendations for implementing design controls at your medical device company, so you can avoid problems later?

LISTEN NOW:

Like this episode? Subscribe today on iTunes or Spotify.

Some highlights of this episode include:

- How do larger companies take on acquisitions when there is little to no Design Control documentation?

- Examples of how to manage up-classification situations, i.e., class I à class II or III and addressing Design Controls

- When should Design Controls begin?

- When to make the transition from "R" to "D"

Buckle in, these guys really know their stuff about medical device product development and the nuances Design Controls can present.

Do you have your own thoughts about Design Controls or medical device product development? Agree or disagree with something your heard in the show? Be sure to let us know in the comments! Both Jon & Mike will be monitoring & responding.

You know, the kinds of problems that could cost you months of runway or even stop your device from being approved by the FDA altogether?

If so, today's inaugural episode of the Global Medical Device Podcast powered by Greenlight Guru is for you.

Jon Speer is a medical device expert with over 16 years industry experience who's played a part in getting 40+ devices approved by the FDA, and he is the Co-founder of Greenlight Guru.

Michael Drues, Ph.D., is a prolific speaker and consultant to the medical device industry as well as being the President of Vascular Sciences.

Join in to hear Dr. Drues and Mr. Speer share some perspectives, opinions, and experiences about various interesting aspects of Design Controls for the medical device industry, including the classic discussion about "research" versus "development" and when should Design Controls begin?

Transcription:

Podcast Topic: Best practices and recommendations for early to next stage medical device companies to implement design controls.

Moderator: Bill Loss

Main Speakers: Michael Drues, Ph.D & Jon Speer

[Moderator Bill Loss opens the podcast]

*

Welcome to today’s podcast, the first in a series focused on the medical device industry. Today’s podcast, ‘Best practices and recommendations for early to next stage medical device companies to implement design controls’.

We are going to cover, going through interesting topics like when and how to think about design controls, how your approach today may limit future opportunity and value in intellectual property, what to do when the game changes.

*

My name is Bill Loss. I've spent the last 20 years in the entrepreneurial world, mostly notably with two successful software start-ups that led to acquisitions by larger players in the respective markets. I am a current investor and advisor in tech space, including the medical device industry. Thanks for listening in! Really excited to kick off today’s podcast.

I am joined today by two industry veterans in the medical device community. First, we've got Mike Drues. He is President of Vascular Sciences and Education Training and Consulting firms servicing the medical device, pharmaceutical and biotechnology industries. Michael has a Ph.D in Biomedical engineering among other degrees from Iowa State University. Mike is an internationally recognized expert and featured keynote speaker on cutting edge technologies and regulatory affairs. Mike is also currently an adjunct professor of medicine, biomedical engineering, and biotechnology at several universities and medical schools.

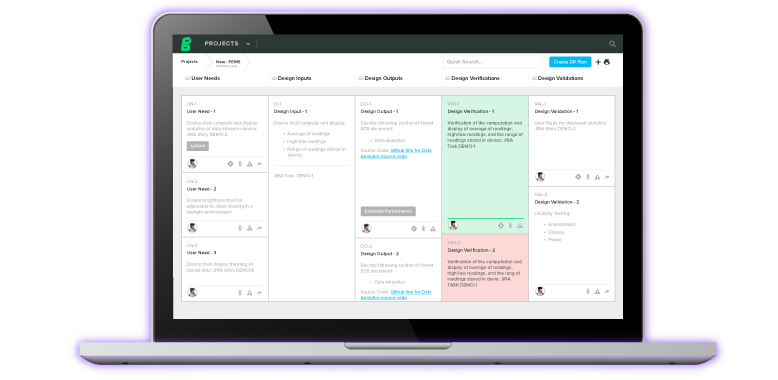

We are also joined by Jon Speer. Jon is co-founder and resident guru at Greenlight Guru. Greenlight offers an innovative approach to eQMS, to delivering a solution exclusively built for medical device community, helping medical device companies get their products to market faster with less risk and better patient outcomes. Jon is also founder and president of Creo Quality, a consultancy formed in 2006 to help support medical device and life sciences startups with product development, project management, and broader operational needs. Jon comes out here with more than 16 years of experience in the medical device fields. Jon has become known as an expert in FDA design control and regulatory submissions such as 510(k) and CE Technical files. Jon also recently authored and published The Ultimate Guide to Design Controls which has been creating some very interesting buzz in the space.

Mike and Jon, thanks for spending some time with us today.

Mike: Thank you, Bill. It’s a pleasure to be with you.

Jon: How are you guys doing?

Bill: Glad to have you both here! We are in the spirit on the fast paced life that everybody lives in, let me jump right in-

Bill: Mike, I want to throw a question over to you, a simple one. When should design control begin?

Mike: That’s a great question, Bill. Thanks again to you, Jon and Greenlight Guru for the opportunity to participate in this podcast discussion today. When design control should begin is an interesting question because virtually to all questions in regulatory affairs, the shortest and most succinct answer is ‘it depends’. Really, it can be thought of in an couple of different ways - from a mechanical perspective or from a philosophical perspective. First, from the mechanical perspective: a strict read of the regulation says that the design controls are supposed to kick in upon project initiation. Now, one can define the word ‘initiation’ in many ways. For example, does that mean when you first come up with the idea for the medical device in R&D? That’s typically not when most people start to think about design controls at a mechanistic perspective. But, on the other hand, from a philosophical perspective, when you think of what design controls are really supposed to do, it’s really design controls as a synonym in my mind for what I call ‘prudent engineering’. That is specs that we should be doing anyway and the regulation reminds us of what we should do, perhaps so that we don’t forget something.

Bill: So Jon, from what Mike just shared, you kind of think about the art versus science for a lot we do in business. What’s your take on this concept of project initiation?

Audio time: 04:52

Jon: It’s interesting. Having worked on a number of projects throughout my career, I've seen a lot of different approaches. Mike is exactly right. It does depend but I think from a practical point of view, there is this fear about when do I start design controls? If I start it too soon, somehow or another that hampers my ability to make progress, or that if I am now under some extreme scrutiny from FDA or other regulatory bodies, I think that fear has caused a lot of debate and a lot of discussion on when design controls begin. To me, the projects work, they are not linear. They don’t go from one step to the next, to the next step, to the next step in a straight line. That seldom ever happens. My thought would be first initiation, once you have a concept or an idea or some sort of user needs or some idea of what you are going to try to solve, from a medical device perspective. To me, there is really no harm in starting design controls at that point of time.

Bill: I guess from a layman’s perspective, you guys obviously bring a lot more clarity to this subject. When we think about how design controls are perceived, you think of necessity for filing and audit readiness or really more of value added in building a better product or both – how do you balance the necessity of what somebody’s regulations that might be placed on us first. Let’s just write forgetting the best product out the door?

Mike: Bill, I will chime in and then Jon, you can follow on. First of all, let me take a half a step back for a moment and just really echo one of the things that Jon just mentioned a moment ago. That is that design controls in particular or regulation in general should not, absolutely not, hamper progress. Unfortunately, this is sort of contrarian to many peoples view today because they look at it as the more regulation or earlier the design controls are required to kick in, the more difficult it is going to be, the longer it is going to take to develop a device, the more expensive it is going to be, the higher the regulatory burden and although I understand why a lot of people think that way, it does not have to be that way. This goes back to what I alluded to in my first comment, and that is design controls in my mind are really nothing more than prudent engineering. Perhaps, I am dating myself here but just for the benefit of the audience, I started out in this business as an R&D engineer in the early 1990’s, long before there was any design controls in place. Somehow, I don’t know how this happened, but somehow we were able to get reasonably decent medical devices onto the market even though we didn't have these thousands and thousands of pages of regulation. Today, we have all of this additional regulation but the question is are our products or are our devices any better? I will leave that as a rhetorical question but it’s an interesting question to ask. Bottomline, the best advice that I can give to the folks that are listening to this podcast is don’t focus so much on the design controls from a regulatory sense. In other words, yes, I understand it is important to follow the regulation, it is important to make sure we have the right documentation, it is important to make sure that we have traceability and all these different things but more importantly, ask yourself as a prudent engineer, what makes sense? What are the things that I should be doing? Then, consult the regulation and use the regulation as a back-up, as a sanity check to make sure that you haven't forgotten anything.

Bill: Very good points there, Mike. Jon, any lasting thoughts here on this topic before we shift gears a little?

Jon: Yes. With prudent engineering, Mike is spot on. I want to emphasize, I mentioned the fear. I think there is this fear about regulation. There is a fear when engineers use this terms ‘design control’. Suddenly that is some sort of complicated, convoluted thing that I struggle to understand. I am just going to say keep it simple, and keeping it simple, design control should just flow with how you are doing your prudent engineering. It has to flow with the progression of an IVS, through the definition or requirements to testing whether or not that product meets those requirements, asking whether or not the product meets the user needs. As long as you keep that continually in your mind, design controls should be something that just happens as part of being a prudent engineer.

Bill: Some engineers are believed to stay in that ((((9:56??? As long as three years????))) stay in research for as long as possible before they believe they can somehow fly into the radar I guess, before crossing over into development. Jon, I gather you have some strong opinions around what many would refer to as ‘making the transition from Research to Development. Would you share a little bit about what the industry is talking about here and why it really matters.

Audio time: 10:22

Jon: There is this long standing belief that...I am in research in medical device product development. As long as I get to say that I am in a research mode, somehow or another, what I am doing is outside the purview of FDA or other regulatory bodies. If I am inclined to believe that, then I may choose to stay in research for as long as possible. Some companies will be very adamant that this product is in research, and it stays in research until we have a proven concept and a proven model, and you've done an animal study, and we have done that. Then, we take it over into development.

Let me get back to our real discussion about when do design controls begin. Once I cross from research into development, then my design controls get, I think it’s interesting. Is that really a pragmatic or practical approach to this topic? Does it really matter if I am in research for this development?

Bill: Mike, I am sure you've got very similar but slightly different twist. What thoughts do you have?

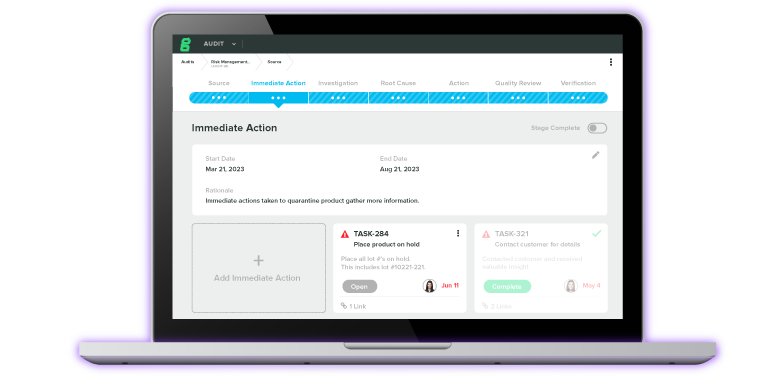

Mike: Thanks, Bill. I will just pick up on Jon’s very last comment. I think it is very apropos. That is, does it really matter if we say we are in research or development. We could easily turn this discussion into a philosophical discussion of what the difference is between research and development. I don't want to do that. But more importantly, we should remember what Shakespeare said very long time ago, and that is a rose by any other name still smells as sweet. So, in a big picture perspective, I really don’t care, quite frankly, if we call it research or if we call it development. What is much more important to me is that we are doing the things that we were supposed to be doing. Hopefully, the regulation will be echoing that. Even if you are working in early research, and let’s be honest. Unlike for example, the pharma or the biotech industries, most medical device companies don’t do very much research. They do a tremendous amount of development but they don’t do very much of research. Even if you are working on the research side of research and development, you should, if for no other reason, be cognizant of design controls because at some point, sooner or later, you or somebody in the organization is going to have to transition from research to development which is definitely when design controls kick in, assuming that you are working on a class-2 or a class-3 medical device. It’s going to make that transition a lot easier to make. If you’ve thought about some of those sort of basic design control 101 issues, even though technically according to the regulation, they might not be applicable in research; and this is why the software tools that you folks are developing, I think really make it beneficial for customers, and for companies to be thinking about those things even in advance of may be when they are required to do so.

Bill: You both brought up the word ‘transition’ and I was just actually speaking to an early stage medical device firm this week. The topic surfaced, how do you get a product from idea stage to something that’s with significant value that a bigger player would want to scoop up, so to speak. Along this thread, Mike, how do you believe larger companies view potential acquisition when there is little to no design control documentation?

Mike: That’s a great question, Bill. As a part-time entrepreneur myself, someone who is involved in starting up several medical device companies, believe me, to quote a famous politician, I feel the pain of a lot of my fellow entrepreneurial colleges because when you are starting from nothing and you are building a prototype in your garage or your basement, you are trying to do everything quick and dirty, and the last thing you want to be doing is spending a lot of time or money on regulatory minutiae, so to say. Nonetheless, in the context of design controls, I think it’s important for even early entrepreneurs to understand that they can greatly maximize the attract-ability, if you will, of their little, new start-up to a potential acquisition, a large medical device company, for example.

Audio time: 15:10

By at the very least having the beginnings of a design control system in place or at least having the pieces of the puzzle in there, so that when the larger company acquires them or swallows them up, once again, it’s going to make it that much easier for them to manage that transition. So, my best advice for the entrepreneurs in this audience is, believe me, I understand, and you probably don’t think this is very necessary. You probably don’t think this is a real good use of your time or your resources but just remember two things: first of all, it will help you to be more attractive to a potential acquisition target. That is the pragmatic response. Perhaps equally if not more important, and that is from a philosophical perspective, going back to what we talked about before, design controls are really nothing more than what I call prudent engineering, what we are all supposed to learn in engineering school although I am not sure if they teach that anymore. Doing the things that we really should do anyway – those are my two best pieces of advice that I can share for the entrepreneurs in the audience.

Bill: Jon, obviously you’ve got a pretty good breadth of client experience directly in the medical device world. How have you seen either document controls being well documented or simply play out in the likes of some of these small, early stage companies?

Jon: That’s a great question considering I am playing a little bit on what Mike has said. I am going to come at it from a little bit of a different angle.

Bill: Having that different angle, Jon, is quite fine. In fact, it’s one of the reasons why we managed to get you guys together here on today’s podcast. I recall a little bit of jousting back and forth over a couple of blog post comments made. It’s great to hear both have similar as well as a little bit of contrasting views.

Jon: Mike and I, we enjoy that kind of jousting from time to time. It makes each of us a little bit sharper. My different take on this is, having worked with a number of early stage startup medical device companies, over the past eight to nine years or so, the early stage companies--the startup-- is often driven behind funding of course. Then they get some sort of funding to get their product to that next major milestone. There is this turn that see medical to emerge, 10 years or so ago, certainly driven from the investment community, I think, that a major funding milestone was this thing called a 510(k) submission permission, granted that’s for a class-2 product. But, startups in the space just glammed onto that because getting their 510(k) submission meant as that was a significant milestone that was directly attributed to their ability to get more funding. I think that that was one piece that really took hold in the industry. Another piece was this emphasis on intellectual property, and getting patents, and things of that nature. I think while regulatory submission and clearance, are particularly important and significant milestones for any endeavor, especially for a medical device startup. The same can be said about patents, I think there was so much emphasis that was placed on those two key pieces of the puzzle that design controls were abandoned. Actually, I had a conversation with a startup yesterday. And they were successful. They got 510(k) submission and they received their clearance. They have no design history file, no design controls to speak of. They have done nothing on their quality system, and now they are interested in being an acquisition target. Suddenly, they have had one of those moments where they realized that they have a ton of work to do because they ignored design controls, because they ignored building a quality system that they are not as attractive for a potential suitor. So, that’s why 510(k) is important, and design controls, in my opinion, are just as important.

Bill: Absolutely, and simply put, I think we all in our professional and most likely for our personal lives as well, have had plenty of those "oh crap" moments where we kind of reflect back.

Audio time: 20:05

We are going to wrap up today’s podcast with sharing some insights on really how to manage drug classifications situations. For example, what we are talking about is a class-1 shifting to a class-2 making a bump to class-3, and what's necessary in addressing design controls. At some phase, it’s really all about what you have. I guess what you claim your device does. Others stress the importance of how additional bells and whistles may be added to your product design, change indications for use, and potentially how the FDA might use classification. Mike, what are your thoughts on this subject?

Mike: Bill, it’s a very good question and since I spend a fair amount of my time working as a regulatory consultant for a wide variety of medical device companies, I see it happens frequently whereas you describe the classification of a device will change, sometimes it will be down-classified, other times it will be up-classified. Sometimes the classification change is because of nothing that the company did. In other words, occasionally FDA will go back and reclassify devices prophylactically based on our experience with the device over a period of time. Other times, the classification might change because for example, we changed the labeling. We go after an indication for the same device but it has a higher risk or we add an additional bell or a feature that justifies the higher classification. So, bottom line, because lower class products, most class-1 devices are exempt from design controls in the regulatory sense. I see a lot of companies that say we are working on a class-1 device, therefore, we don't have to worry about design controls. If they find themselves in one of the scenarios that I just described, now they might be working on the same or similar device but now class-2, and all of a sudden they are in the wonderful world of design controls. Once again, I go back to what I talked about before: whether technically you are responsible for following the design controls or not really shouldn't matter. It shouldn't be the most important thing that we think about. What should matter is that we have the systems in place that Jon was describing earlier and that the software, or the product that you guys have that helps people to develop and to maintain. We have all of those systems in place, including quality and so on and so forth so that if we are in one of those situations, it makes that transition that much easier. One last thing that I will mention is I find a lot of the companies that I work with, they get so focused on bringing their current device onto the market that they really don't even think about the challenges for line extensions or new products that might arise following that market. As Steven Covey used to say, ‘begin with the end in mind’. So yes, I certainly understand the pragmatic importance of putting most of our eggs into current basket that is focusing most of our attention on the device that we are trying to get onto the market right now. But we should always have at least one eye to the future and be thinking about what could change or what bells and whistles and features might we add or what indiction might we go after in the future that might kick us from the world where we don't have to worry about design controls very much to the world that we do.

Bill: Jon, Mike brought up an interesting theme around down-classification which is really something that I hadn't thought about. Obviously, in an ideal world, keeping things as simple as possible would be probably preferred on the medical device company side. What one single thought would you really want to hang your head on when we talking about either up or down-classification that you might want to leave the audience with?

Jon: One thought, you put me on the spot though. One thought. The class doesn't matter. You have to look at design controls as really a foundation, and I go back to early on in my career sitting in an audit and going through--it was an ISO audit in this case--we were going through design control, design history file with the auditor, and the auditor asked me a question, and I am like yes, we did that, and the auditor was like, show me! Basically, don't tell me, show me.

Audio time: 25:00

And, design controls is what that is all about. Mike referenced a couple of times today prudent engineering. If you are a prudent engineer then design controls part and parcel of how you do your job. It’s the proof, it’s the evidence that your product does what you say it’s going to do, and that should be irrespective of whether your product is class-1, class-2 or class-3, whether it’s US, whether it’s Europe, or whether it’s Canada. It really doesn't matter. Design control is a universal practice that allows you to prove that your product is safe and effective.

Bill: At the end of the day, that’s the game we are all in here, trying to make sure that we are bringing products to market as fast, as best, and ultimately with the best patient outcomes. With that Mike and Jon, thanks so much for spending time with us. Your insight obviously is interesting and definitely appreciated. Those of who you are listening in, thanks for your continued feedback and shared enthusiasm. Stay in touch with Mike. You can check out more of what he has to say on his guest column at medical device online magazine, or connect with him on LinkedIn. You can check out more of Jon’s writing at blog. Greenlight Guru or ping Jon on LinkedIn. Stay true to your roots till next time, let’s all work together towards improving the quality of life on earth, and who knows, maybe even beyond.

About the Global Medical Device Podcast:

The Global Medical Device Podcast powered by Greenlight Guru is where today's brightest minds in the medical device industry go to get their most useful and actionable insider knowledge, direct from some of the world's leading medical device experts and companies.

Like this episode? Subscribe today on iTunes or SoundCloud.

Nick Tippmann is an experienced marketing professional lauded by colleagues, peers, and medical device professionals alike for his strategic contributions to Greenlight Guru from the time of the company’s inception. Previous to Greenlight Guru, he co-founded and led a media and event production company that was later...