How Surgical Innovation Associates Found the Benefit of Quality Beyond Just Compliance

In this episode we continue our series on the new breed of medical device companies who are getting more done by working smarter. Newer companies and entrepreneurs can have a lot of insight for all of us on what works, what doesn’t work, and what’s important to the people new to the industry.

Jon Speer talks to Alexei Miodinow from Surgical Innovation Associates, who is on his first journey through the medical device product development process. Alexei shares some of the stories and challenges that comes along with tackling the process for the first time.

Listen Now:

Like this episode? Subscribe today on iTunes or Spotify.

Some highlights of this episode include:

- Alexei’s background and some information about Surgical Innovation Associates and what they’re working on.

- What led Alexei to take the step from being a surgeon to becoming a medical device developer and inventor.

- How Alexei’s approach to solving problems and looking for direction might be different than the typical approach, and his best tips for entrepreneurs who want more than just “the common startup.”

- Alexei’s thoughts on quality vs Quality when it comes to medical device development and production.

- One of Alexei’s biggest frustrations (that turned into one of his biggest surprises) about the process of medical device development.

- What Alexei is hoping to see and accomplish in the future as he continues to work with Surgical Innovation Associates on medical device development.

Related resources:

Surgical Innovation Associates

Memorable Quotes by Alexei Miodinow:

“So few people know anything about Quality with an uppercase Q.”

“Not knowing how to do something is not equivalent to not being able to do it.”

“What started off as a bureaucratic “check the box” exercise turned into something that guided product development.”

Transcription:

Announcer: Welcome to the Global Medical Device podcast, where today's brightest minds in the medical device industry go to get their most useful and actionable insider knowledge, direct from some of the world's leading medical device experts and companies.

Jon Speer: Hello, this is Jon Speer, the founder and VP of Quality and Regulatory at greenlight.guru, and welcome to another episode of the Global Medical Device podcast. Today, I'm thrilled to have one of our new breed medical device companies and able to feature them. With me, I have Alexei Miodinow. He is with the Surgical Innovation Associates and a first time journey through the medical device product development process. So, I hope you enjoy the few minutes that I have to chat with Alexei and hear some of the stories and the challenges that they're going through and how they're just kicking ass in the process of tackling everything that comes their way.

Jon Speer: Hello, and welcome to the Global Medical Device podcast, this is your host, the founder and VP of Quality and Regulatory at greenlight.guru, Jon Speer. And today, we are continuing our series on the new breed of medical device companies. And I have a wonderful guest with me today, Alexei Miodinow with Surgical Innovation Associates, also known as SIA. Alexei, welcome to the program.

Alexei Miodinow: Thank you for having me, Jon.

Jon Speer: Well, Alexei, the world is dying to know. Tell us a little bit about Surgical Innovation Associates, a little bit about what you're doing, and talk a little bit about your background and your team's background, and how you got to where we are today?

Alexei Miodinow: Absolutely. Surgical Innovation Associates is very much a for surgeon, by surgeon company, kind of as the name suggests. And so what I guess our core focus is taking to market a clinically superior and more cost-effective means of soft tissue support in a variety of procedures, both reconstructive and cosmetic. So a lot of work in both the general and plastic surgical spaces. And our first products, which actually is kind of pretty steadily coming to fruition now, is a transient soft tissue support scaffold or a mesh made of a bioabsorbable synthetic material.

Jon Speer: Yeah. It's been awesome to be a part of your journey, even from a bit of a distance, but to see that. I mean in my career in this space, I've worked with a lot of physician-inventors, but very few who have really taken the bull by the horns, like you have. So, for me, that's been pretty awesome to see how you've just taken ahold of this. You go into this with a learner's, at least from my perspective, from a learner's mindset, you realize there's a lot of things that you don't know, but you're a student and you're willing to figure out what it is that you need to know, understand what the obstacles are in front of you, and then you just tackle it full steam ahead. I love that.

Alexei Miodinow: Absolutely. I think it's an important part of all of our mentalities here on the team, both full-time employees and advisors, mentors, my co-founder. It's just really important to not just know what you don't know, but be willing to go figure it out.

Jon Speer: Yeah. Yeah. And I guess, I'm always curious as to what led inventors and entrepreneurs to take that next step. 'Cause that's... I mean, the... Forgive me, but the idea is easy sometimes, right? It's going and executing on an idea that's hard and you must have felt enough pain as a surgeon dealing with these sorts of issues, that became challenging. So what was the trigger?

Alexei Miodinow: Oh, absolutely. So I... In the interest of full disclosure, I Alexei Miodinow not the inventor of our first products.

Jon Speer: Okay.

Alexei Miodinow: In fact, my friend, mentor and kind of leading thinker in plastic surgery was the one that invented this device. And it was in my role actually as a student, at the time I was an MD, MBA student at Northwestern, that's what led me on to this project. Having done years of work with him, having faith in that experience of the problems that are out there and of the now patented solution, so that's kind of the impetus that carried me through to the point that after business school, I said, "Instead of finishing up clinically, I will put that off at the moment and try to take this idea and make it a reality in the hands of surgeons everywhere." It was also along that pathway that my stellar colleague, Todd Cruikshank, who has about 10 years of the industry experience at Baxter and then Baxalta, joined the team, and we basically made up the core management for what is now a multi-product company that's moving right along.

Jon Speer: Yeah, that's cool. And you and Todd, we've... Obviously the greenlight team, we've had a lot of interactions with you. I know you worked pretty closely with our customer success team in a number of areas. But again, it's that spirit that you approached this. I mean, you're entering into a product space that at least, from my little bit of knowledge about, it's a little crowded in some respects, but it's not very... Well, there's not been... And my opinion, again, hasn't been super innovative or super creative on the solutions. And I'm sure, in that respects, that's pretty exciting for you guys.

Alexei Miodinow: Absolutely. Having this great idea to run with that is conceived in the operating room by someone who witnesses the both clinical and cost-related problems every day in this space is just an unparalleled opportunity. So it's exciting to have something that's differentiated in multiple ways. To see that this industry does have a lot of hand-to-hand kind of combat amongst them.

Alexei Miodinow: But, at the same time, that there is room for something and there's a calling for something like our first product, the Tissue Maker, so...

Jon Speer: Yeah, yeah, that's cool. And I can imagine when... I think we got connected pretty early on in your journey into this med device adventure, right?

Alexei Miodinow: That's right. One of your other stellar clients, Dan Holton, connected with me, actually.

Jon Speer: Oh yeah, that's right. I forgot about that. Yeah. Yeah, Dan's... Dan's with Cypris Medical, they're, I mean, he's killing it right now. They're doing fantastic work. I guess I probably shouldn't use killing in a discussion of medical devices. So I'd say he's crushing it right now in a good way. So...

Alexei Miodinow: Indeed, yeah, with a caveat, it's probably okay. [chuckle] Yeah, it was Dan that introduced us, because we were... He is actually in a similar space in terms of the kind of aesthetic, implantable surgical device arena. And we were on the search for, not only a quality system, but for information on what exactly a quality system is, you know?

Jon Speer: Yeah.

Alexei Miodinow: That's what, that's what led us, ultimately, to your doorstep. It must be eight long months ago, something like that.

Alexei Miodinow: It's funny, like everybody knows that they want to bring a product, a quality product to market, but that quality is with a lowercase Q.

Jon Speer: Yeah.

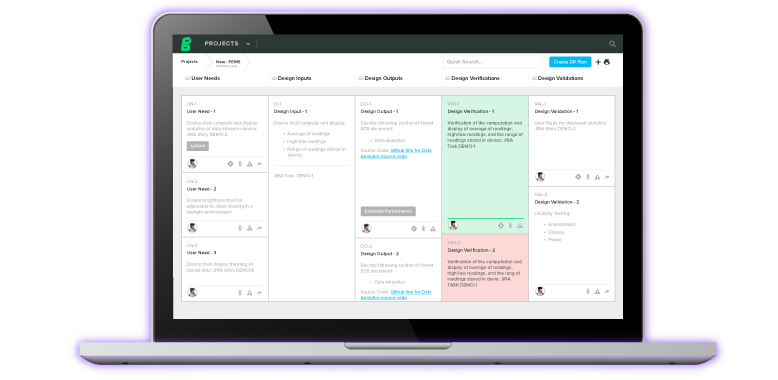

Alexei Miodinow: So few people know anything about quality with an uppercase Q, which is obviously what... I count myself among those people. And it's with greenlight.guru, that I've slowly tried to bring myself into the other bucket of people that kind of understand what that means, and why it's important. And I know Todd also has just taken a lot from this journey. It's kind of been... It's not just a... For someone, I imagine, that has a lot of experience in this space, it's a passive implementational kind of thing, but for us, as people that are new to this startup medical device world, it's very much an instructive and strategic thing.

Jon Speer: Yeah. And you said it's been eight months. I can remember the first call like it was yesterday when we first got connected. And from that first conversation that I had with you and with Todd, it was just... You approached it from a different perspective. And that's one of the things that I wanna try to... I hope that the listeners to this podcast pick up on that, because you and Todd have... You come into this saying, "Hey, we don't know what we don't know." And getting a little bit of guidance and direction from us and from the other advisors and the other people that you're working with, and then you go and figure it out. And, for me, that's been awesome to kinda see. And I wonder if you can talk a little bit about that, I mean, is that just the way you were born? Is that how you were wired? Or is that something you picked up on through your education process? What tips and tricks can you provide to other entrepreneurs and inventors and other startups out there who are trying to do the same sort of thing? What is it about you that... And you don't have to be modest, I know you want to be, but you don't have to be. What is it that makes you tick? How do you go about life this way, that makes you just a little bit different than the common startup that's out there?

Alexei Miodinow: I appreciate that, I'm... It's a good thing this isn't a video 'cause I'm blushing. I guess I would say it's a hard question to answer and a good one. Perhaps to be on the level of introspection of which I'm capable. I think certainly the education system in which we grew up has a lot to do with it. Coming from the scientific curiosity of medicine, going to the kind of strategic broad thinking at Kellogg Northwestern, it definitely gives you a toolbox for how to think about things, and understanding that the fact that you don't know something, or that you have never done something, is not equivalent to not being able to do it or not being able to know it.

Jon Speer: Sure.

Alexei Miodinow: So I'm sure there is some degree of upbringing in that equation also, in case Mom's listening or something. Hello, Mom and Dad.

Alexei Miodinow: I certainly acknowledge that. The nature and nurture thing that comes into play. But overall, yeah, I would just say to anyone, either in this position, far beyond this position, of which there are many, or perhaps kind of considering jumping into something like this, that pretty much everything in life can be figured out with the appropriate amount of work and thought and, when appropriate, a request for help from people that know what they're doing.

Jon Speer: Yeah, I think that's pretty insightful. And that's something that... My upbringing is similar. I had a very blue collar upbringing and my dad and my mom both taught me hard work pays off, and it certainly does, but one of the things I've learned throughout my life is sometimes it's okay to ask when you don't know, and sometimes there are people who are out there that can help you that are willing to be a resource for you. And so it sounds like you've had similar sorts of experiences.

Jon Speer: I wanna dive a little bit more into this big Q quality versus little Q quality, and let's peel back some layers to that. Now, little Q quality, I think anybody that's passionate about what you're doing and passionate about your device, or the product, or the issue that you're trying to solve, from a medical perspective, I think we're all pretty ingrained with this little Q quality that's just gonna be part and parcel to what we're doing. But you said something...

Alexei Miodinow: Yeah, I like to hope that there are very few people that say, "I wanna bring a sub-par medical device to market," or, "I'm out here... I'm out here to take mediocrity and put it in surgical hands everywhere." That's probably not so much the goal.

Jon Speer: Yeah, I don't think it is either. So I think... Let's just make an assumption that most everyone who's in this space, there's someone, at least somewhere in that organization, that's very concerned about little Q quality. But you said something about the big Q quality was maybe, we'll say an a-ha or something that wasn't quite obvious when you first started this journey. Let's talk a little bit about that, and can you share a little bit about how you even came... You mentioned Dan, obviously, Dan Holton at Cypris talking to you and suggesting some things, but it had to be something else along the way that was maybe thrilling or maybe frustrating in this journey with that big Q quality. Can you talk a little bit about that?

Alexei Miodinow: Yeah, absolutely, I'd love to, 'cause it's... This is one of the failures of others that we got to learn from instead of failures of ourselves and those are the best kind.

Jon Speer: Yeah, for sure.

Alexei Miodinow: For sure. So I can tell you that our concern about this kind of mystic, ambiguous quality system thing and how it pertains to the development and, ultimately, the clearance of our device, those concerns started years ago, actually, before the product was even conceived. And they started with another company that one of our close mentors and advisors was involved in, kind of a motley crew of underground entrepreneurs like ourselves, certainly, who brought a stellar device to market and had a deal in place with a large medical device manufacturer for distribution licensing that ultimately was rated by the Navy windbreakers emblazoned with yellow FDA letters in this NCS style way, basically to find to find what you might call in this political climate an alternative quality system.

Jon Speer: Okay.

Alexei Miodinow: And you can imagine that that didn't... That didn't end well at the time for that company, although they had a great device, a lower case Q quality device. The quality system didn't actually support market entry. And now that company is actually doing great, and it's doing great because it was taken over by a sharp CEO. One who not only is sharp, but has a 10-plus year background in quality and regulatory for both large and small medical device manufacturers. So you can see the shift there in that. Their current success is very much one of turning around that aspect of their business. And so, having learned that lesson, fortunately, anecdotally rather than personally, it was just something that we wanted to get right, but didn't even understand eight or nine months ago.

Jon Speer: Yeah, those stories and those experiences where you can live somewhat vicariously and see what somebody else has done and not have to make that mistake, those are certainly valuable, and it's good that you were able to pick up on that without having to go through that kinda pain and suffering. Alright., so we've been at this or we've had a relationship with you now, as you mentioned, for several months. So share with me maybe something that's been one of your biggest frustrations through this process. Does something come to mind? Or maybe it's surprise, maybe frustration isn't the right word, but something that's been surprising to you. Has there been something that sticks out?

Alexei Miodinow: I think that those two... Maybe there's some degree of frustration that has tacked on maybe a pleasant surprise in retrospect. I think that comes from our initial lack of understanding of what a quality system is and how it interfaces with your product development, how it interfaces with your plans for testing and ultimately helped us a lot. And that's happened in multiple ways. If you just take one example, let's say, of the risk matrix and what is a risk matrix, right? It's this thing where you grade these hazards and they go all the way downstream to patient harms, and you link them through these foreseeable events, and then you ultimately have to grade them on probability and severity. And it all seems very bureaucratic, I guess is a good word for it.

Jon Speer: Sure.

Alexei Miodinow: The face of it, coming, obviously, coming from a clinical side and then having to think through what seem to be obvious situations, but then assign somewhat arbitrary numbers to them, and things like this, right? It seemed initially like something that was just a frustration that needed to be done for documentation purposes.

Jon Speer: Right.

Alexei Miodinow: But it needed to be done, A, that's one good thing about this. But, B, it turned into a very useful exercise, I think, against my own expectations. And that's because along the pathway to forming that risk matrix, there were legitimate concerns raised about the types of packaging that we chose, and what might happen to them under specific sorts of environmental conditioning. And it led to us circling back to our subcontractor to get some more specs on that and do a little bit of stress testing just to make sure, ultimately, that when we go to production, we don't get a nasty surprise. So what started off as a seemingly bureaucratic, check the box kind of exercise, turned into something that somewhat guided product development, and I think that happens with many parts of the quality system, and I appreciate that.

Jon Speer: Well, thank you for sharing that story. And as you were sharing that, I was thinking, "Well, this example that you're sharing with the audience, is certainly a place where little Q quality and big Q quality collide in a good way," right?

Alexei Miodinow: Exactly.

Jon Speer: And I guess to go a little bit further, as you were sharing that story... 'cause I think a lot of companies, whether they've done this before, or haven't done this before, they look at quality, big Q Quality and quality management system, and risk management, as all these things you have to do, sometimes they lump that in the bucket of pain and suffering and bureaucratic and overly burdensome, and all those sorts of things. But when you have that experience of, where you can see that the activity... And you go into it with that learner's mindset like you and Todd have done so well, you go into it realizing, "Hey, there's gotta be a purpose behind this." And then you see, "Oh, wow, this will help me determine what I need to do from a testing standpoint," or, "Hey, this helps me figure out I need to add this sort of design feature, or maybe we need to do this or that," it helps guide and improve the overall product, and that seems like a bit of an a-ha moment or a green light, maybe pop alive over your head, something like that.

Alexei Miodinow: Yeah, I think that's absolutely the case. And like I said, it's not only been the case specifically with risk management nor has it been the case specifically with packaging, it's really been true across our design and development phases, and all the related activities that we've done.

Jon Speer: Thank you for sharing that. So, last few minutes of our discussion today, I just want to applaud what SIA is doing, and I think the speed in which you're doing it. For me, again, I've been doing this a while, I've brought a lot of products to market, and the fact that you and Todd are able to... And the rest of the SIA team, I know you've got a whole wealth of resources that you're tapping into. The speed in which you're doing this is, for me, impressive. From our first conversation, to now, eight months later, where you are in that process, with the product that you have that, let's be real, it's a complicated device. It's got a lot of things going on with it. There's a lot of testing, and performance, and all these sorts of things that are certainly gonna be a factor with that. But you're marching very quickly toward your first 510k.

Jon Speer: So toot your own horn a little bit. Tell me about your path to market and what you see in the near term future, and maybe a little bit longer, beyond that initial lens, where things are going, and how things, you see them progressing from a process perspective.

Alexei Miodinow: Absolutely. So, as you mentioned, we are relatively near our first 510k submission, although it doesn't feel that way in the time horizon of a medical device company, we're certainly getting there, and that's exciting. So kind of in a similar fashion to the way that I talked about the circular iterative feedback cycle between the quality system work, and our product development work, there's been feedback cycle between these surgeons who we speak to, who have advised us, who have invested in us, both time and money, and there's been a feedback cycle between their enthusiasm and their ideas about what we're doing and follow-on products.

Alexei Miodinow: So at this point, we have a product that's very similar to the currently developed one, but for slightly different clinical and surgical scenarios, and we have one that's dissimilar, but has some portfolio synergies in the aesthetic space, and I won't talk too much about those two products, for reasons you can understand, but long story short, part of that feedback cycle has now left us with not one but three products that, if fundraising and regulatory stepping stones fall into place appropriately, can all go into market kind of consecutively next year, which is obviously very exciting. It positions us to either be the start of a standalone company in this space, or potentially pursue a licensing deal with either a large strategic, who might be able to use these products in their bag, or a smaller company that perhaps has biologic products and might realize, again, some of that portfolio synergy of being able to also have a synthetic product offering. We're gonna evaluate those opportunities as they come, and as our regulatory and then product milestones, allow for.

Jon Speer: Sure. For me, I love that approach, and I think that that's why I view SIA as one of these new breed of medical device companies. And let me summarize that by saying, you're figuring out how to get things done, you see what the obstacles are, you figure out how to tackle those obstacles, you leverage your resources, you tap into new resources as needed, but you're all about trying to get that first product to market, and I love what you said at the beginning about being a product for surgeons, by surgeons. That's so key, you've got your finger on the pulse of the end user, and you're using that end user to guide and direct the strategic direction of your business, so that... Just get the first product out there, get it into the hands of the end users, and at the same time, innovate and evolve your product offering, so that you've got multiple options, and issues, and clinical needs that you're addressing and solving, and you're just iterating and learning, iterating, learning. And man, it's exciting to work with companies that have that sort of mindset. So thank you, I love the opportunity that we have at greenlight to be able to work with Surgical Innovation Associates. So thank you for that.

Alexei Miodinow: And we love working with you so... So yeah, I appreciate everything you do and thank you for having me on.

Jon Speer: Yeah, absolutely. Any parting words that you wanna share with our listeners before we wrap things up today?

Alexei Miodinow: Yeah, I guess, not sure how to quite phrase this. I guess I don't know the audience composition, and far be it for me to proselytize about my views on entrepreneurship, being in my young and relatively inexperienced position. But I think this is relevant to your listener base as greenlight.guru, and to many people that are in universities maybe thinking about doing something like this. I guess I'd say that, in the stage that's as early as SIA is, we might start our days as accountants and be lawyers by noon, and then Todd might be an engineer making 3D prints, and I'm a researcher taking microscopy photos, and by the time we've convened at the end of the day as basically beggars, and of course, by beggars I mean dressing like you have millions of dollars to meet your dinner guests who you hope will just give you a couple grand so you can hit the next milestone.

Alexei Miodinow: And I think a big part of that is this idea of being lean and just as efficient as possible with your capital. The notion of virtual companies in the medical device space seemed ridiculous a few years ago, but because of cloud-based platforms like greenlight.guru, because of experts like you, and Jesseca Lyons, who I have to give a shout out to, because she's an awesome part of your team. The notion of a virtual company and being able to bring a lower case and upper case Q quality product to market, with just a shop, with just a couple of people, and a lot of expertise supporting them, it's not impossible, and I just think that's an important lesson for people that have an idea and maybe are thinking about what they can do with it, but might be misguided in thinking that to hit some early milestones, they need millions of dollars.

Jon Speer: Well, that's great advice, and it certainly speaks to the entrepreneurial spirit that you and Todd, and the Surgical Innovation Associates team has. So, I wanna thank Alexei Miodinow for being my guest today on the Global Medical Device podcast. Do go out and check out what Surgical Innovation Associates is doing. I know some of it's clandestine and not necessarily available, but do pay attention, because I firmly believe that the SIA team will be changing the surgical world here very soon. So Alexei, thank you. And for those of you like Alexei, or who are interested in figuring out a better way to manage your big Q, quality management system, certainly go to greenlight.guru, make a request, we'll be happy to talk to you about our platform, the services that we provide, and we would love to share in your journey in bringing your medical device to market as well.

Jon Speer: And once again, this has been Jon Speer, your host, founder and VP of Quality and Regulatory at greenlight.guru, and this has been the Global Medical Device podcast.

About The Global Medical Device Podcast:

![medical_device_podcast]()

The Global Medical Device Podcast powered by Greenlight Guru is where today's brightest minds in the medical device industry go to get their most useful and actionable insider knowledge, direct from some of the world's leading medical device experts and companies.

Nick Tippmann is an experienced marketing professional lauded by colleagues, peers, and medical device professionals alike for his strategic contributions to Greenlight Guru from the time of the company’s inception. Previous to Greenlight Guru, he co-founded and led a media and event production company that was later...