Look, I get it.

Worrying about implementing a quality management system isn't on your list of the top 23 items you need to focus on right now for your medical device.Worrying about your animal study is more important.

Worrying about your first in man clinical study is more important.

A QMS is something you will get to. Eventually. Once your product is much closer to launch.

A QMS is just noise right now.

Those other items are much more important, and you will catch up your QMS efforts later.

Suuure.

Because everything below won’t really matter to you. Your mind is already made up. If you believe any of those statements, then maybe you shouldn’t continue reading this post.

Oh, you’re still here. Smart.

If you are serious about being a medical device company, then you should be serious about implementing a QMS - yesterday.

Maybe you haven’t made progress on yours because:

-

You are not familiar with the quality system regulations and requirements.

-

Hiring a consultant to establish your QMS is too expensive at this time.

-

It seems like a huge waste of time, effort, and energy based on your current phase.

Let me offer one key tip here: Bootstrap your QMS--build it as you need using a purpose built solution like Greenlight Guru.

Making the investment in a quality solution you can use today as well as while you grow will save you from the nightmare that comes with implementing a paper-based approach, which is not only the riskiest, but the most expensive way to manage your QMS.

5 reasons a QMS is key to your success

-

It establishes your company processes in a way that aligns with regulatory expectations.

-

It establishes a framework for how you do business.

-

It defines expectations and deliverables for key processes.

-

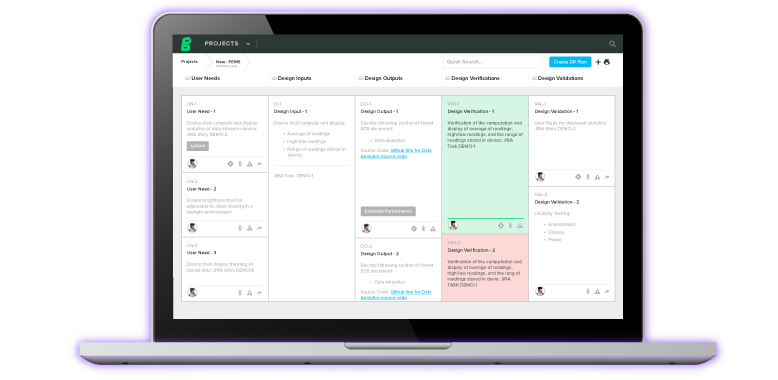

Documenting Design Controls + Risk Management are key to product development success. And both are also critical parts of building a QMS foundation.

-

QMS efforts need to start during product development and evolve as you get closer and closer to market release.

1. QMS Aligns with Regulations

Having a QMS is a requirement for a medical device company.

It is not optional.

You would be surprised how many companies believe that their med device is not “significant” enough to need a QMS.

Being a medical device company means certain expected behaviors are required. And having a QMS that aligns with regulations is definitely an expected behavior.

FDA 21 CFR part 820 and ISO 13485 both define requirements and expectations for a QMS. It’s a best practice to establish your QMS to align with both.

Here’s some good news: If your QMS meets FDA and ISO 13485, then there is a pretty good chance you are going to be in good shape with most medical device regulatory bodies.

2. QMS is a Framework

The overall purpose of establishing a QMS is to establish the framework and requirements of your medical device company.

Your QMS establishes your company processes. Your company rules. Your company expectations. How you do things. What documents and records you generate.

Establishing this framework is important. Establishing this framework early is key.

It’s not too early to start your QMS. Now is the time.

3. QMS Defines Expectations & Deliverables

Building your QMS early has two primary advantages.

-

Your QMS framework sets the expectations and lays the ground rules for your resources.

-

You start generating critical documents and records as objective evidence to support decisions and submissions.

The QMS processes define what documentation is required.

QMS defines who need to review and approve documentation.

QMS defines what records you need.

4. Design Controls + Risk Management

If you are developing a medical device, then you absolutely have to establish QMS procedures for Design Controls and Risk Management. These are the most important procedures for you to define and implement ASAP.

It doesn’t matter how early you are or if you are in “research” mode or still doing “feasibility” studies.

Even early, capturing Design Controls and understanding Risks are essential to your overall success.

You are developing a medical device. You need that medical device to work. You need that medical device to be as safe as possible.

Design Controls and Risk Management QMS processes guide you through product development to ensure these needs are addressed, with documented objective evidence to support you.

5. Evolution of QMS

Your QMS should evolve and grow with you as your medical device travels through product development and into production.

Start small in the beginning. Focus on 4 key areas of your QMS during pre-production stages:

-

Document Control & Records Management

-

Design Controls

-

Risk Management

-

Supplier Controls

Continue to build the QMS from there.

I recently talked to this guy who realized he needs a QMS but had never created one. So he read FDA 21 CFR part 820 and ISO 13485. He then proceeded to author a whole binder full of procedures to address the requirements. But he admitted that the QMS binder of procedures sat on the shelf and no one in the company ever cracked it open.

Don’t be that guy.

Your QMS needs to be useful and used.

My advice is to start small. There is nothing wrong with a simple procedure as long as it addresses what needs to be done and is followed.

Maybe you’re thinking putting together your QMS is too daunting.

They’ll be sure to let you know that our solution comes with all the procedures, forms and templates you need to implement your QMS today among many other benefits.

If you are still thinking this QMS stuff isn’t necessary for you at this time, then I wish you luck in your endeavors. I’m sure FDA will understand your excuses when that inspection happens.

Jon Speer is a medical device expert with over 20 years of industry experience. Jon knows the best medical device companies in the world use quality as an accelerator. That's why he created Greenlight Guru to help companies move beyond compliance to True Quality.

Related Posts

What Does a Risk-Based QMS Mean?

Design Controls Need to Start With User Needs

13 Tips For Audit Etiquette Every Medical Device Company Should Know

Get your free PDF

Content Toolkit for Medical Device Startups