What Medtech Startups Should Know About Quality Systems To Not Go Overboard

MedTech startups thrive on lean-ness.

Part of lean-ness is knowing how and when to scale regulatory and quality requirements for your business while maintaining practical compliance and manufacturing safe and effective products.This article takes a brief look at a withdrawn FDA Guidance called, "Medical Device Quality Systems Manual: A Small Entity Compliance Guide" to show you how to get the most out of your quality management system.

From the manual:

“FDA also recognizes the continuing need to use innovative approaches, particularly in dealing with small businesses that could be unnecessarily adversely affected by federal regulations. It is hoped that the information in this manual will assist manufacturers in their efforts to establish and maintain a quality system that enhances business.”

Wait…the FDA understands that small business are...small?

The FDA gets a bad rap sometimes from the healthcare industry. Yet, time and time again – within inspections or within published guidance and documentation – I’ve seen the agency be cognizant of the issues facing non-Medtronic sized corporations.

The QMS Compliance Guide is a great example of the FDA trying to remove the regulation police handcuffs while stressing that the intent of the quality management system (QMS) regulation 21 CFR 820 (Quality System Regulation, or QSR) is not to be burdensome but to promote a quality culture that manufactures safe and effective product.

How?

The FDA acknowledges the little fish in the big pond, too!

The story is too common. I meet a new client looking to implement a QMS. Said client says something along the lines of: “Well we spoke to someone else and they also said we need X, Y, Z, XY, XI, 94, LS…” – you get the point.

Often, because many folks are not intimately familiar with the QSR, Compliance Guide or any of the other peripheral guidance on QMS, they attempt to fit a Medtronic-sized (using Medtronic because they are massive – love you guys/gals!) QMS into a pre-revenue start-up manufacturing well Class II devices in a well understood product category!

The depth and breadth of the QMS being implemented should reflect your company size, product risk, regulatory climate (ex: if you were manufacturing breast implants in the 80’s/90’s you probably wanted to be a little more rigorous with your QMS due to highly scrutinzed field issues) and other similar factors.

In fact, check out the Compliance Guide and what it says about this topic:

“Typically, large manufacturers will have a quality system that exceeds the medical device QS regulation. Small manufacturers will typically have a proportionally simpler system. FDA recognizes: that a small manufacturer may not need the same amount of documentation that a large manufacturer does in order to achieve a state-of-control; and, that some of records maintained to fulfill the GMP requirements for written procedures may not be as long and complex for a small manufacturer.”

Bingo!

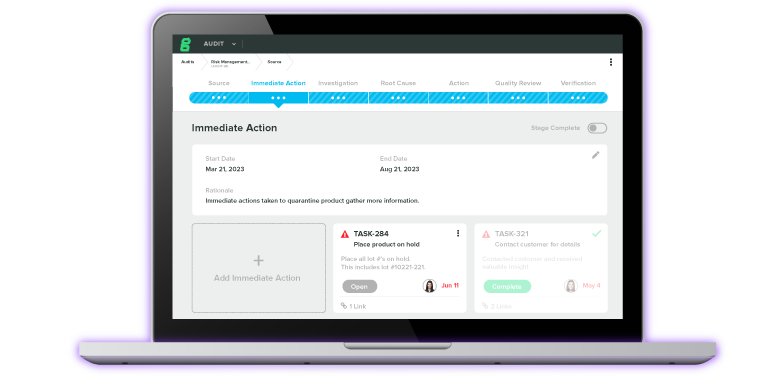

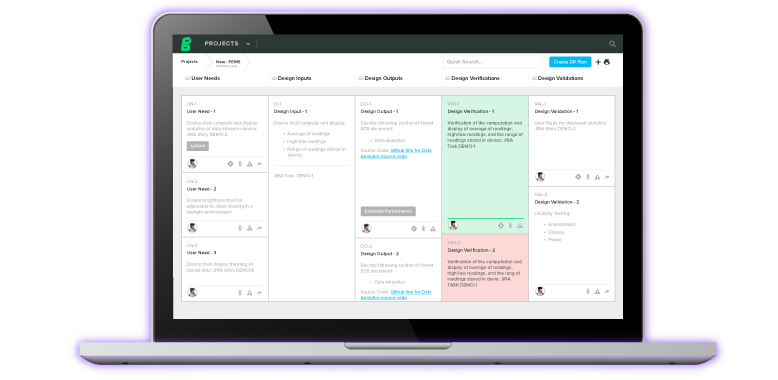

As a practical example: often, I’ll find that an effective Design Controls program at a small company can be accomplished using an SOP and some supporting templates for guidance.

For contrast, recently when I did some remediation work for a Fortune 500 company, their 820.30 system was comprised of an SOP, (4) instruction procedures, (10) templates and several validated software programs.

Is one “more compliant than the other”?

The FDA – and me – say a resounding NO.

Flexibility of the GMPs

Scale of QMS applicability also means there is flexibility and how and when they are applied.

GMPs – good manufacturing practices – are defined in the QSR for medical devices.However, as described in the section of the Compliance Guide, “…because the QS regulation covers a broad spectrum of devices and production processes, it allows some leeway in the details of quality system elements.”

The best way to address and implement a flexible QMS is to determine which subparts are applicable to your company and have documented justification for why the other’s don’t apply.

Do this within a Quality Manual or a Quality Policy – a highly visible document that broadly describes your QMS.

I love the following example which is an excerpt from the Guide that illustrated the acceptability of scaling:

“For example, if it is impossible to mix up labels at a manufacturer because there is only one label or one product, then there is no necessity for the manufacturer to comply with all of the GMP requirements under device labeling.”

This essentially applies to 95% of start-ups that are usually launching only one product when it comes time to create their first QMS.

SUMMARY

Don’t be fooled or stressed when it comes time to implement a quality management system at your small company.

The QMS should be scaled to reflect your company and product’s characteristic….even the FDA says so!

Even though it was withdrawn, review the plethora of useful info in, "Medical Device Quality Systems Manual: A Small Entity Compliance Guide" to learn more about how to frame your QMS appropriately while keep your business compliant and effective!

Editor's Note: This guest post by David Amor, CEO of Medgineering and Quick Consult, is being republished with permission. It was originally published on their blog here.

David Amor, MSBE, CQA is a medtech/biotech consultant and mobile health entrepreneur who founded Medgineering, a company focused on remote compliance, regulatory, and quality systems consulting for larger companies and start-ups. A graduate of the prestigious Innovation Fellows program at the University of Minnesota’s...